cut 22 gauge sheet metal They can easily cut through 26 or 29 gauge metal panels, and probably heavier. But there is a RIGHT way to do it! We highly recommend reading this article and watching the videos before you start snipping away at your new metal roof . Benefits of metal fabrication career longevity, including paid training, competitive wages, strong culture, work-life balance, advancement opportunities, and more.

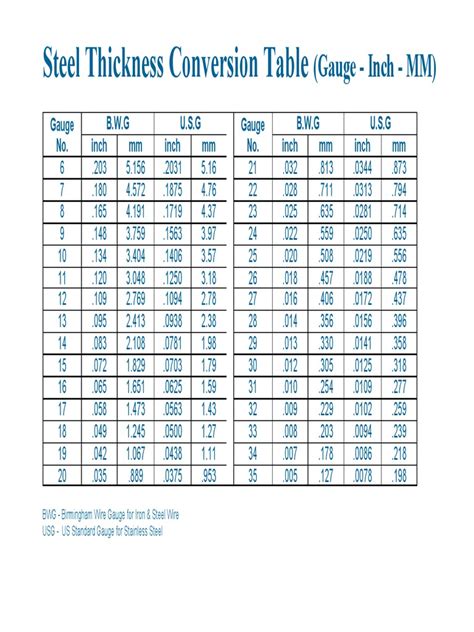

0 · gauge 22 thickness in mm

1 · 22 gauge thickness in inches

2 · 22 gauge sheet metal thickness

3 · 22 gauge sheet metal prices

4 · 22 gauge sheet metal 4x8

5 · 22 gauge galvanized steel sheet

6 · 22 gauge galvanized sheet metal

7 · 22 ga galvanized sheet metal

In short, CNC machining is a metal fabrication method where written code controls the machinery in the manufacturing process. The code determines everything from the movement of the cutting head and the part to spindle speed, RPMs, etc. CNC machining services use a subtractive fabrication method.

In this How to Cut Sheet Metal using different metal cutting tools article, we shared our practical experience with few important FAQs.

Depending on the pattern and type of sheet metal, you can use several different kinds of equipment to make a cut. You can use an electric saw for simple lines, or you can try tin snips, dremels, or metal nibblers for complex . Today I’ll go over three different tools you can use to cut sheet metal and plate.

Cutting out damaged sheet metal and trimming patch panels can be done many ways. This article covers the pros and cons of the most popular methods, as well as a few less popular methods. Air Cut-off ToolThey can easily cut through 26 or 29 gauge metal panels, and probably heavier. But there is a RIGHT way to do it! We highly recommend reading this article and watching the videos before you start snipping away at your new metal roof .

Avoid accidentally bending, scoring, or gouging the metal in your next DIY project when you follow this technique for how to cut sheet metal. There are a couple of different types of bits that you can use with your Dremel to cut sheet metal. One of the best things that you can use is a heavy-duty emery cut-off wheel. Another thing that will work really well for . Most strong and thick sheet metals will require power tools for cutting, such as an angle grinder, band saw, rotary tool, circular saw, or chop saw. I used 22 gauge cold-rolled steel sheet metal for demonstration purposes and different common household tools to cut it. There are many ways to cut sheet metal, which one you need to use depends on the project. The following is a primer of tools and techniques for cutting sheet metal. The most important factor to consider when working with sheet metal is the gauge. The lower the number, the thicker the metal is.

A circular saw is ideal for cutting all gauges of sheet metal, even the thickest of sheets, and it is ideal for cutting straight lines. If you have pieces that need to be separated into various sections, then this is one of the best methods that you have at your disposal.

In this How to Cut Sheet Metal using different metal cutting tools article, we shared our practical experience with few important FAQs. Depending on the pattern and type of sheet metal, you can use several different kinds of equipment to make a cut. You can use an electric saw for simple lines, or you can try tin snips, dremels, or metal nibblers for complex designs with curved lines. Today I’ll go over three different tools you can use to cut sheet metal and plate.

Cutting out damaged sheet metal and trimming patch panels can be done many ways. This article covers the pros and cons of the most popular methods, as well as a few less popular methods. Air Cut-off Tool

They can easily cut through 26 or 29 gauge metal panels, and probably heavier. But there is a RIGHT way to do it! We highly recommend reading this article and watching the videos before you start snipping away at your new metal roof panels. It’ll make the job much better for you! Tin Snips 101 – What Are Tin Snips? Avoid accidentally bending, scoring, or gouging the metal in your next DIY project when you follow this technique for how to cut sheet metal. There are a couple of different types of bits that you can use with your Dremel to cut sheet metal. One of the best things that you can use is a heavy-duty emery cut-off wheel. Another thing that will work really well for cutting sheet metal is a 1-1/4-inch cut-off wheel. Most strong and thick sheet metals will require power tools for cutting, such as an angle grinder, band saw, rotary tool, circular saw, or chop saw. I used 22 gauge cold-rolled steel sheet metal for demonstration purposes and different common household tools to cut it.

There are many ways to cut sheet metal, which one you need to use depends on the project. The following is a primer of tools and techniques for cutting sheet metal. The most important factor to consider when working with sheet metal is the gauge. The lower the number, the thicker the metal is. A circular saw is ideal for cutting all gauges of sheet metal, even the thickest of sheets, and it is ideal for cutting straight lines. If you have pieces that need to be separated into various sections, then this is one of the best methods that you have at your disposal. In this How to Cut Sheet Metal using different metal cutting tools article, we shared our practical experience with few important FAQs.

houzz metal beach house sign moddern

Depending on the pattern and type of sheet metal, you can use several different kinds of equipment to make a cut. You can use an electric saw for simple lines, or you can try tin snips, dremels, or metal nibblers for complex designs with curved lines. Today I’ll go over three different tools you can use to cut sheet metal and plate.Cutting out damaged sheet metal and trimming patch panels can be done many ways. This article covers the pros and cons of the most popular methods, as well as a few less popular methods. Air Cut-off ToolThey can easily cut through 26 or 29 gauge metal panels, and probably heavier. But there is a RIGHT way to do it! We highly recommend reading this article and watching the videos before you start snipping away at your new metal roof panels. It’ll make the job much better for you! Tin Snips 101 – What Are Tin Snips?

Avoid accidentally bending, scoring, or gouging the metal in your next DIY project when you follow this technique for how to cut sheet metal.

gauge 22 thickness in mm

$399.99

cut 22 gauge sheet metal|22 gauge thickness in inches